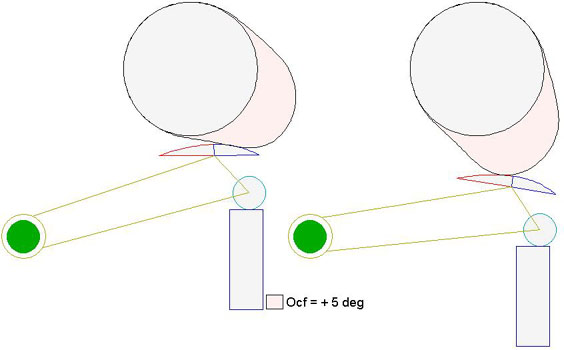

Example of a Finger follower design with a compound (2 radii) pad (back)

This

is the in-software information picture which accompanies the input data

fields for the geometry of the "type 2" finger follower. Note that the

cam follower pad has two radii where the confluence point of the two radii

can be offset by an angle Ocf. For the sequence of pictures below, all

input data is common except for the numerical value of Ocf.

(back)

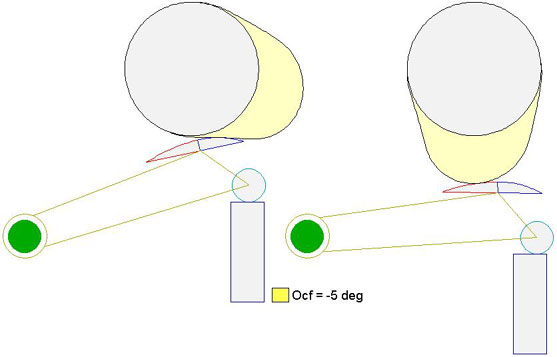

This

shows two snapshots from the on-screen movie of the cam profile design

and the lifting of the valve when Ocf is -5 degrees.

(back)

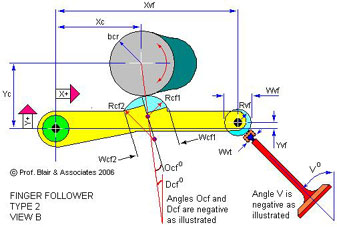

This

shows two snapshots from the on-screen movie of the cam profile design

and the lifting of the valve when Ocf is +5 degrees

(back)

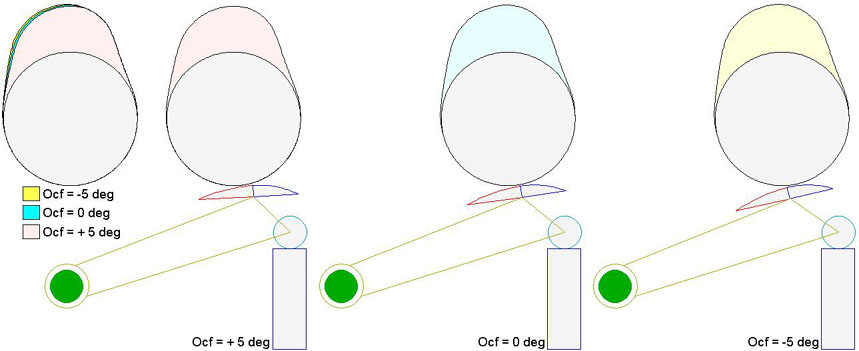

This

shows the cam profile designs when Ocf is -5, 0, and +5 degrees. The movie

snapshot is taken before the commencement of valve lift and where the

tappet is set clear due to the input data valve lash. It is now obvious

that the cam profile design is a function of this offset angle Ocf with

consequential shifts in Hertz stress, oil film

thickness, radius of curvature, etc., all of which are computed by the

4stHEAD

software (back)

©Prof Blair & Associates