Update 9 - Summer 2011.

Time flies and then you realize it’s time again for another update. Looking back this winter was again one better to forget as quick as possible but on the other hand it makes the workshop behind the house an even more attractive place to be.

This is great for the V6 projects!! But also my son’s 50 cc racer got a different style and looks fresh and orange now and he already has had 4 races with it.

On a regular basis, people from different backgrounds with different interests, are visiting the Laverda museum. Mid December I had some Belgium quests and while talking I discovered that this very kind Laverda man was a talented aluminium welder. I quickly had a phone call with a person who knew him very well and he agreed this should be my man. When I asked Jef if he was prepared to weld both rear frames, in which also the oil-tank houses, his reaction was; “ I’ am very pleased to help you on this point ”.

And so I finished some other activities and on Christmas day I made a start drawing up the side panels on AutoCad and studying lots of photo’s and factory drawings that I have from the prototype oil tank/seat. I quickly discovered drawings and photo’s of the prototype were 2 things, there were a lot of small differences and also in 1977 improvising was necessary. The other oil tank of the 24 hour V6 racer looks actually equal to Piero Laverda’s one but at the inside parts were missing and the whole part was made in 1991 out of steel plate as opposed to the aluminium one of Piero. I decided to renew this one as well.

My time in planning stuff is always quicker then the reality and with several problems to be solved the pieces of the puzzles were finished after 12 weeks. Right now all the pieces are in Belgium ready for welding.

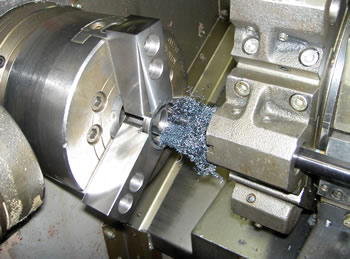

Another crankshaft ball bearing was needed but I knew it has been a “special”.

With great help and a long research of my well known supplier a search was started at SKF Sweden but these advised to ask SKF Austria, then Germany, then Belgium.

And after more then 1 month finally the important message came through. In Belgium where as we now know the drawings were stored ………..only this drawing was missing but someone with a very good memory could remember that a couple of years ago some of these bearings were still in stock in Rome. So in my best Italian I wrote mail and yes! After having received the parcel unfortunately the inner diameter still had to be 3 mm. bigger from 30 to 33 mm. In the eastern part of Holland I found a specialist for this who guaranteed to grind within a concentricity of 0,002 mm.

The bearing is ready now to be built in. By the way, the original V6 crank bearing had been ground too but I hoped the Italian bearing with equal SKF number was ready to assemble.

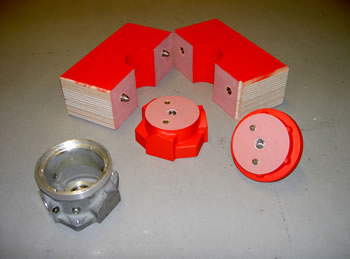

Also Breganze, where I was end of March for a while, they have done their best to cast 4 distributor housings from a wooden mould that I made. 2 of these will be machined in the coming months and I also will make an injection mould to make some new rotors.

My valuable contact from Magneti Marelli helped me a lot with important information and he made new drawings to change the rotor a little because of the new ignition system that Uwe Witt in Germany is developing for the V6.

Against all expectations, the V6 prototype gets more theoretical shape already. My plans were to continue this beautiful Laverda six cylinder after having finished the 24 hour V6 racer because there are a lot of extra problems with this bike. As said, unexpectedly the rear frame and oil tank will be finished soon and someone showed up who will recalculate the whole swing arm and mono shock system that wasn’t working at all when the bike was on show at Milan in 1977. The handling of the bike was terrible then but……….. who cares when its only on display at the bike-show? This absolutely should be changed now, as it has to be ridden too!

Machining of all parts for both machines is slowly getting to an end and I am already dreaming of assembling the first V6.

Will be continued……………………………….

Cor Dees

April is a beautiful season in our area.

.jpg)

Aris’ racer, unfortunately Aprilia but bright orange.

From plastic material a mould was made to cast some new distributor housings.

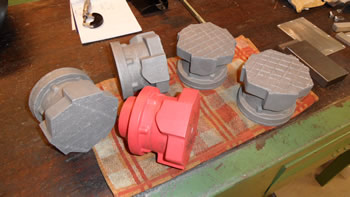

Finished moulds.

Castings for distributor housing.

Many thanks to Hans for plotting exact 1 to 1 pictures of the Laverda V6 prototype.

.

.

I was allowed to do the rolling and bending of the sheet metal plates myself at a friend’s workshop.

Old and new seat/tank.

Prototype frame and seat.

The new made prototype petrol tank was checked in combination with the new seat/oil tank.

New oil pick-up screens for the oil tanks.

Prototype seat and oil tank almost complete.

V6 – 24 hour type almost complete in bits and pieces.

Brother and sister ready for welding.

My welding master “Jef “ inspects my work!!!!

Turning the two bearing halves with help of a diamond-tipped tool. After this the inside diameter had to be ground precisely to size.

Both bearings ready for assembly.