Some more positive news!

Dear readers,

The months fly by which is a good thing given the weather has been bad for too long in the Netherlands. From last October till the end of March it was too inclement for motorcycling and so I was able to spend a lot of time in the workshop. The result now is that important matters have been more or less concluded and some light can be seen at the end of the tunnel.

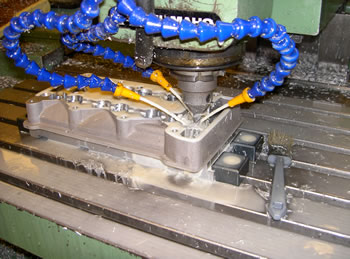

The front housings are, beside some little work, finished. Because they forgot, or whatever, to cast in the transit channel for the liquid system I had to make this through a “backdoor” operation. After this operation the backdoor was closed by welding. Then the work pieces were left in my wife’s oven (she was shopping) for a couple hours to reduce any stress from the welding and after that the whole piece could be finished and precision holes could be bored. After that, the long oil holes were also made and as such these housings are nearly finished now.

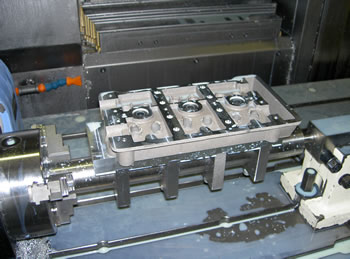

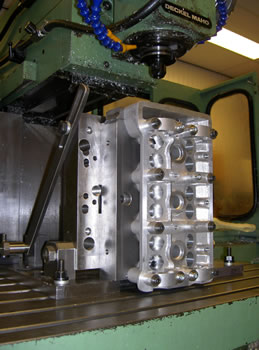

From the 4 castings that I have for the camshaft supports I started with machining them all, afraid that I was to have 1 or 2 rejects with the final line bore. This was for me a totally new experience too and could only be made at the end of the job. After many, many hours of making precision jigs I could finally start with machining the 4 castings. Many drawings first had to be made on my AutoCad system to produce the right program for my milling machine.

The jigs were all finished by grinding in my friend’s workshop. Sometimes, at the end of the day I thought by myself : “what did I do today“? But this is how it works.

These 4 castings took about 180 hours of my time!!

The oil pump of the latest V6 seemed to have some serious damage and had to be replaced, and because my second v6 project also needs one a new series of 3 was started. The oil pump housing contains 2 oil pumps - a dry-sump part, and the high pressure part.

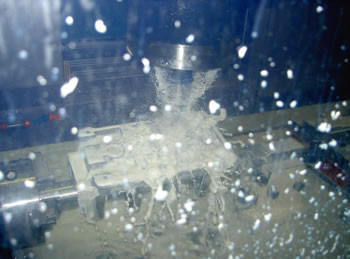

It became a job again with many hours behind the computer working with my AutoCad system. Also a very accurate jig had to be made and ground to make machining of the aluminium plates possible. 5 Different plates finally will house the gears and bearings and will be assembled without any seal or gasket. That’s why they have to be produced within 0,01 of a mm and may not warp!! This was a big deal and I had many worries about it but in the end the result was perfect. The new pumps I have made carry several improvements, notably in the bearings, in comparison with the unuseable one from the latest V6. I'd like to extend my heartfelt thanks to Adriano Valente, head of the drawing office

of Moto Laverda at that time, for his herlp.

After another month this job is nearly finished as well.

There are many future things my head is already working on, or things you think; "Can't this be done in a different way?". For example, with the future assembling of the crankcases the splash plates have to be mounted first in the lower crankcase. Because of that you cannot see what you are doing when you assembling the cases together. I don‘t like that! Also the front housing is very tight on the inside where the oil pumps are. Other matters are problems with the ignition that Uwe Witt is making for me, the 8 camshafts that I have are computerised and now a good valve diagram can be made. The old paint of the latest V6 engine is now removed and I figured out the ratio for the rev counter because I have several different shafts. They all cannot be used. New cam followers are ordered and many mails were sent to the crank maker who has already 4 months delay. Another nice experience was the finding of a second fuel pump on an Italian swap meet. This all after 2 years with lots of help from Breganze people but they all couldn’t tell me where to find it and what it was used for. They called the pump-factory at Torino but even they could not tell them where it was used for. They shopped everywhere without success and then………there it was ….and I was there too!! Until today I do not know in what vehicle or engine it was used. It all remains exiting.

In addition to all this of course, was the Laverda Museum with all the visits of clubs and other visitors. Mid April I had a visit of the AJS/Matchless club with 60 people, 2 other times visitors from Breganze and many others from all over the world!! Another job is to prepare the Laverda sidecar racer with its SFC works engine for Spa Francorchamps this year . The sidecar will be ridden by its Italian first owner, Vanes Vincenzi and as sidecar passenger the Aermacchi Museum owner Jaap de Jong during the GP Parade on June 12th and 13th.

Will be continued……………………..

Many regards,

Cor Dees

The “backdoor”is closed by welding.

In my wife’s oven any stress by the welding were released.

No marriage-stress was followed up by my action.

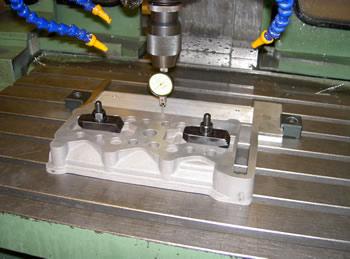

The front housing can be finished and precise holes can be bored.

A prototype front housing at top right in the picture. You can clearly see the different position

of the distributor in opposite to the other 3.

.

.

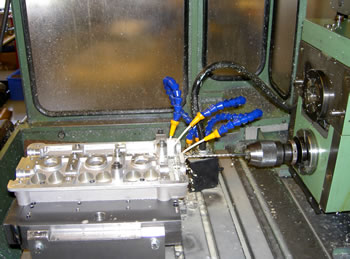

Milling oil return slots into the bottom side.

.

The small castings in process and finished at the end.

Boring one of the oil holes

A very small carbide cutting tool of ø3 mm had to be ground. As I do not have a tool grinder at home the grinding disk was mounted on my milling machine.

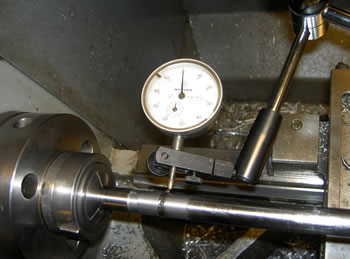

The ground line bore tool with the small carbide cutting tool was adjusted on my lade.

Testing the line bore.

No test but reality!! Fortunately they are all good.

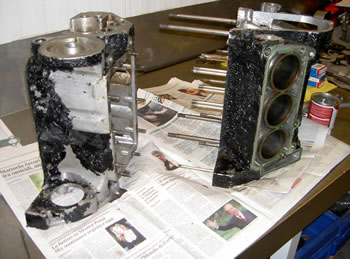

Just a small job on the crankcase.

Milling the outside contour of the much thicker dry sump part.

Nearly finished. All parts together here.

And then it is April and all the country side around us is coloured every year.

This time we had hyacinths.