Gearbox....

Work currently focuses on the gearbox, producing not only all the missing gears for this bike, but also a modified version of the gearbox for Piero's V6, as well as some spares.

On the nineteenth of November 2007, Gijs van Dijk and I went to Breganze. We visited Piero Laverda, because we wanted to see the partly dismantled original V6.

Together we plan to also improve Piero's V6, which now does the rounds of the promotional events. Piero Laverda had opened the Laverda V6's gearbox to see whether the close ratio box could adapted to be a little more like a street version. Given the sort of demos and processional rides the bike now often does, first gear is too tall.

With the help of 3 former employees the required data was collected and we tried to find a solution. Adriano Valente, former manager of the drawing room, is 75 years of age but he still has a bright memory. Fernando Cappellotto was a testrider on the V6, and has considerable experience with the machine, while Antonio Segalla was the mechanic of the Laverda V6 and is proving invaluable as we delve into the past to reconstruct and improve what was done exactly 30 years ago.

As most of you know I have, for some years, been working on a third Laverda V6 as well. The makings of this bike were the remaining stock of parts after the second bike was built in 1991. I started this work when I never imagined to have the opportunity to purchase the second complete bike. I intend this "third" V6 to become the same as the original prototype of 1977 that was shown at the Milan show (see picture on homepage).

And so, for myself I have to make 2 complete gearboxes including clutches, shafts etcetera. Piero also needs some gears, so in total I need to make 3 to 4 gears each including some spare parts. On CNC lathes and milling machines the materials will be made into these parts. After that splines and teeth had to be made into these gears and then hardened and ground. Lots of work and time with these activities but a lot of fun!!!

To be continued………

Cor

February 2008

At Breganze the magnesium wheels of this V6 have been checked by X-ray for cracks. Result, everything OK!!

A wheel being placed into the X-ray machine for checking.

Adriano Valente examines the gearbox.

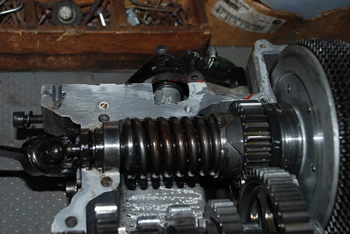

The cush drive and clutch release mechanism of Piero's V6.

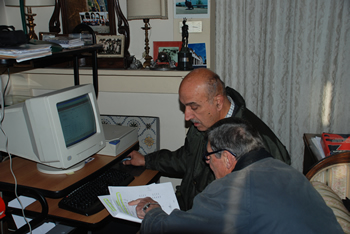

Piero and Adriano work on the revised ratios for the more practical gearbox.

A good opportunity to make a valvediagram of the V6 . Collecting every bit of data now makes it easier later on.

Antonio Segalla rotating the cranckshaft again.

Gijs van Dijk counting teeeth on the gears.

Here we can see the engine without front cover, exposing the drivetrain for the engine ancilliaries. The oilpump is already removed.

The inside of the oilpump is pretty worn and will be replaced. Also the shaft with the big gear had some serious wear and has to be renewed as well.

A part of the clutch cush drive. The pair of these cups are visible in the photo on the second row above, held together by a spring. This removes shock loadings from the driveline.

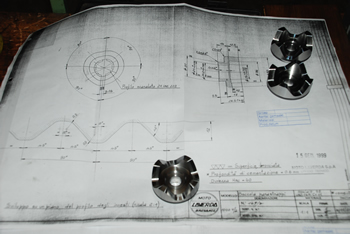

This part can be made in one setup using a CNC lathe with "live spindle tooling".

In process. 4 clutches . 1 For Piero, 2 for me plus 1 spare.

Gears and some more gears in process!!

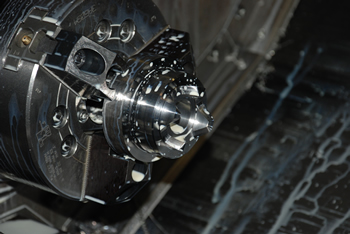

Mazak CNC lathe at the machineshop, with the growing pile of gear blanks in the foreground. The teeth are cut in a seperate process.

First of all the selector forks have to be drawn up to calculate the coordinates for the Deckel milingmachine.

Cutting the selector forks.

After lots of drawing and calculating you finaly have some products. Not finished yet but it starts looking like it.