Update 12 - January 2013.

Dear readers,

As expected, the last few months had been filled with museum days, my sons racing and also becoming active again in my former machine shop. In the Netherlands we have half a million unemployed at the moment but no skilled people available. I enjoy being back in my old job together with my former employees and I really do like it. It is just for a couple of days a week, but together with the aformentioned things my V6 project has slowed somewhat.

But every free minute has been spent on both V6’s and there is not a day without something happening toward the V6 project - there is always a thing to be done or to ring about. And through it all I spent lots of hours on the project and so more progress has been made.

Both distributors are finished and are now in Germany to be completed with the electronics. They really look identical to the original one.

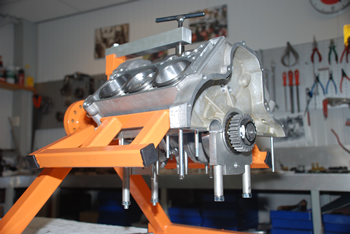

The engine has assembled further. Crank, con rods and pistons are in their position and everything has been checked.

Both, rear frames, petrol tanks and seats have been at the paint shop to put everything in the base paint. Seats are covered in their original design.

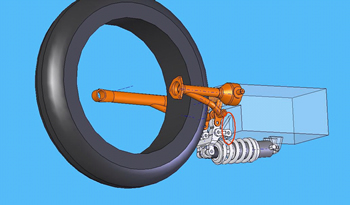

Another thing that would take a lot of time was the rear suspension of the prototype. Tyl Schimmel is an enthusiast member of the Dutch Laverda club that has skills on engineering level and knows a lot about suspensions. Over a year ago I approached him about the Prototype's original monoshock suspension and studied the system and found that the design could not work. Although in 1977 these mono shock systems were at a starting level and not working well, this one worked reversed! For the Milan exhibition no problem but on the road it could not be used. So that is the reason Moto Laverda developed a new suspension for the bevel shaft driven V6’s that was mounted on the 1978 and 1991 V6 racers.

Tijl immediately suggested the prototype swing arm is too short but I didn‘t want to change the shape of the bike so we have to deal with that. I told him I do not want to ride this bike at a speed of 283 km/h but I do not want to die at 200 km/h. It is not a promise it will work perfect now but I am deeply impressed at the work he did. It looks great and I have now started making parts for a new prototype swing arm and other parts that will be needed to link the swing arm to the shock absorber.

When I bought the parts from the factory in 1999 I wanted to wait disassembling the 2 complete 34 mm heads until most of all other parts were made and finished.

I know myself and I didn‘t want to have another mountain of parts in my work shop.

I now regret I do not have disassembled the heads earlier because I now found out the valve stem seals of the Corteco brand are not available anymore. The sizes that have these seals are not common and after 6 hour of research behind my computer there is no result yet. On this moment I do not know yet how to solve this problem but finally there will be found a solution. Every day is a new day with new surprises.

Next months I will open the throttle and so I hope to have more positive news to tell you.

Many regards and may be will meet you in the Laverda museum.

Cor Dees

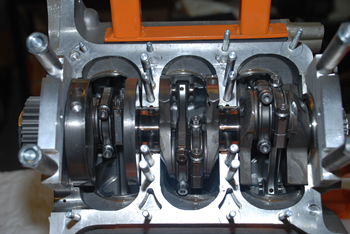

With the assembly of the piston it appeared the chambers in the piston for the exhaust valves were not big enough and had to be machined to the right size.

All plays have been checked in an earlier stage and so we now can bring the pistons and their con rods on their final position.

The con rods were tightened and their bolts were checked on their extended length with help of a micrometer.

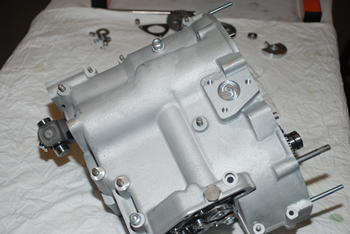

Everything has got his position now and the crack cases can be closed.

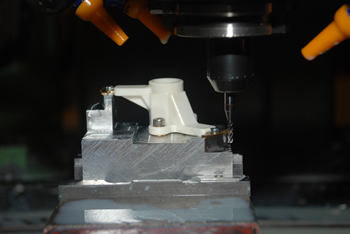

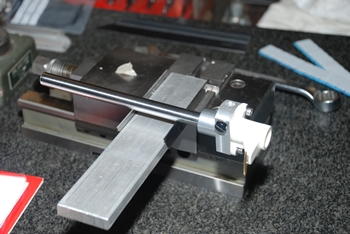

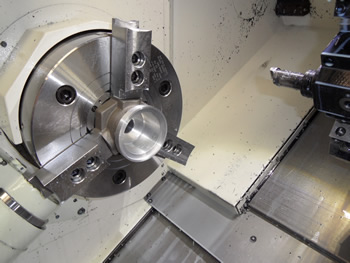

Everything has got his position now and the crack cases can be closed. The final step for the distributor rotors. The outside diameters were milled on a small jig.

The final step for the distributor rotors. The outside diameters were milled on a small jig. The rotors and the rotor base plate were balanced.

The rotors and the rotor base plate were balanced.

3 Distributor housings have been turned and milled. Two complete distributors will be produced.

For the high tension part of the ignition new housings had been milled because I didn‘t want to change the original old Ferrari ones.

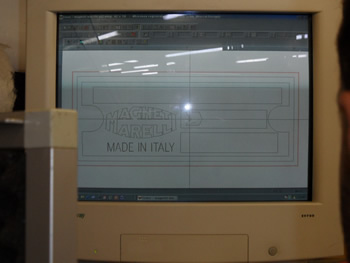

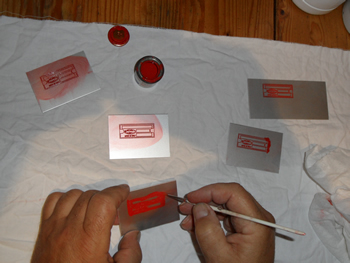

To make the distributors as original as possible new “Magneti Marelli “ type plates were engraved.

Assembling the new distributor.

The result after a, in terms of time, incredible ran out of control part.

Tijl Schimmel has done a great job to judge the complete suspension system of the proto type V6. And with help of the “Solid Works “ 3 dimensional drawing system he calculated everything on strength. I’ am quit convinced this system will do his job quite well.

Because of a too short swing arm the system will never be perfect but it will be any way much better then the original one. Changing the length of the swing arm is not a question because this will harm the shape of the prototype.

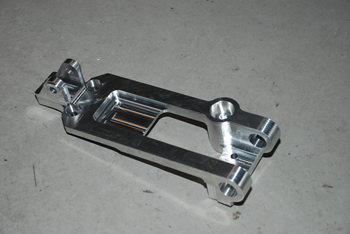

The bridge that will be needed to keep the mono shock in position beneath the gearbox.

From 10 kg 7075 aircraft aluminium a final product remained of 600 grams.