Update 10 - November 2011.

Dear readers,

Again another half a year since my last update and fortunately there is more news about the V6 project and progress to report. Even though I have been slowed down by the racing weekends with my son Aris, the garden, some weeks of holiday in Italy where I went with 11 other Laverda 100 riders from Milano to Taranto, and other things not the least of which many visitors to the Laverda museum.

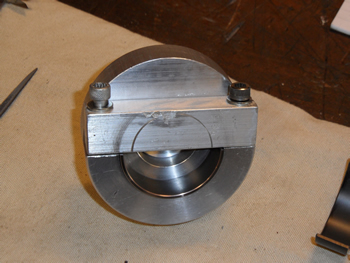

It took almost one full month to make an injection mould to produce a couple of distributor rotors. The mould was ready 5 months ago but the wait for material has been a pain since this only goes in large quantities and 5 or 6 rotors are by no means a large quantity! Last week the supplier told me that he finally found a supplier of the material in Germany. Let’s just hope nothing goes wrong with the mould as normally injection moulds are made from hardened steel but this time I have chosen to make the 5 rotors in a mould made from aircraft aluminium. It is perhaps a bit of a gamble but it will certainly reduce costs and saves me a lot of time.

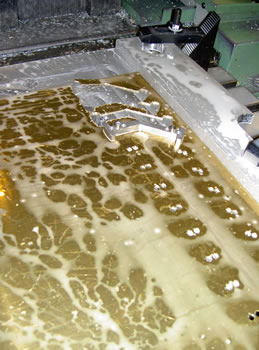

In the lower part of the crankcase there are 3 different sump baffle plates which make sure that oil that going into the sump does not get mixed up with air. I had the plates laser cut, then used a roller press to make strengthening profiles in them. After that there was some welding and I had to make the plates fit into the crankcase. It was a special job but I am very happy that it is finished.

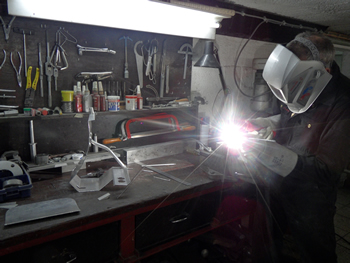

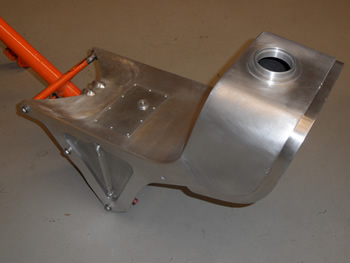

At the end of august I got the rear sub-frame from the 24 hour version back from the Belgium welder “Jef”. I am extremely satisfied with how the finish looks and Jef certainly has done a great job. I am really happy with it and with him! The seat of the prototype will arrive very soon as well.

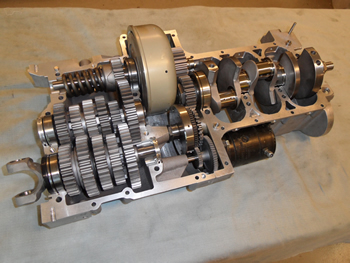

At the beginning of September there was the celebration of the 30th anniversary of the Laverdaclub at the Laverda museum. It was a wonderful event and almost 100 participants enjoyed and had a wonderful day. To honour this event I completed the lower part of the engine provisionally so a quick look could be taken at the inside of Laverda’s V6.

I had a special meet at the beginning of July. Just before the start of the Milano-Taranto run I met Mr Natale Parolini, the man that worked at Magneti Marelli in the seventies and that still knew a lot about the distributor of the V6. He spent a lot of time helping me with developing the new rotor and other things for the distributor. It was good to meet each other after so much mail contact all those years.

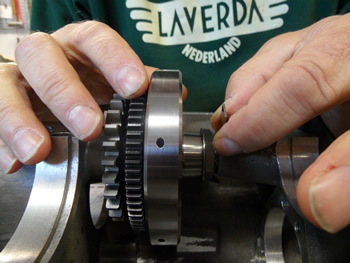

Both versions of the V6’s have my attention, so I worked on both gear boxes, made dozens of shims for both, hardened and ground them, made several manifolds for the liquid cooling system and lots of other items.

If we have a bad winter a lot of progress will be made in the next six months!

I will keep you informed.

Many regards,

Cor

Father and son at the end of the 4 hour race on the circuit of Croix (France)

Out of a sheet of brass metal new rotor tips were milled.

.

.

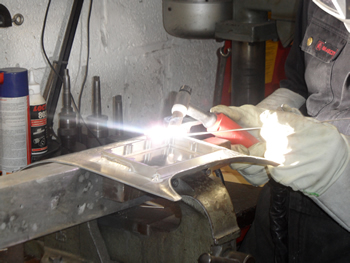

Belgium welder “Jef” welding the prototype seat.

A fter hours of welding and polishing the result is there. Jef has made a great job and I am glad the seat and oil tank of the 24 hour model V6 has be come original again inclusive all filters and other internal parts.

In honour of the Laverda event I roughly put together the lower crankcase and gear box and supplied them with internals to show the driving train of a Laverda V6.

With help of gauge blocks the exact width of the required gearbox shims shims were defined.

The oil baffle plates were first laser cut from flat sheet, then rolled to the correct radius, then I added these stiffening ribs.

With some handwork the grooves were opened a little.

Retired Magneti Marelli man, Mr. Parolini who was a great help for me redesigning the rotor and designing other parts for the V6 distributor.

After 1750 km on the Laverda 100, this is the finish in Taranto. At a temperature of 45 degrees C !!

On our trip we met 2 guys from Breganze, Gianni Radin (white shirt) and Flavio della Costa (orange shirt). They specially came down to Bologna to meet us.

Rest all Laverda 100 riders from Switzerland, Germany, Holland, New Zealand & England.

12 Riders depart from Milano and 12 riders arrived at Taranto !!