IntroductionLowering a car is a common practice when trying to improve the handling or the appearance. In some cases, this is done by cutting the springs that came with the car. In this article, I will be looking at the problems caused by using cut springs. Table of ContentsAssumptionsFor simplicity, a few reasonable assumptions will be made in this article.

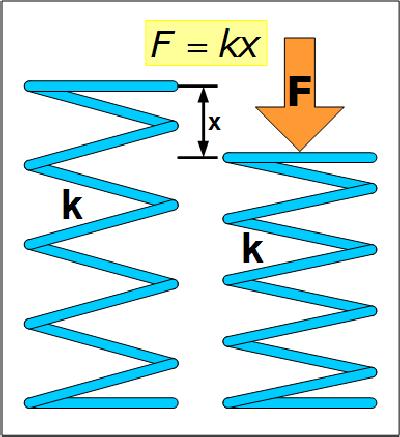

How Springs WorkA spring is a mechanical device that absorbs energy by deflecting a certain distance. Springs have a property called a spring constant which is a ratio of the force applied to the deflection distance. A higher spring constant implies that the spring will have a lower deflection distance for a given applied force.

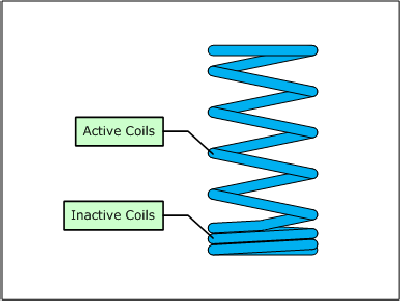

The magnitude of the force and the spring constant determines the compression distance of the spring. The spring constant varies with the diameter and length of the wire, the material, and the number of active coils. An active coil is one which has not bound to an adjacent coil. In this article, it is assumed that all coils remain active throughout suspension travel.

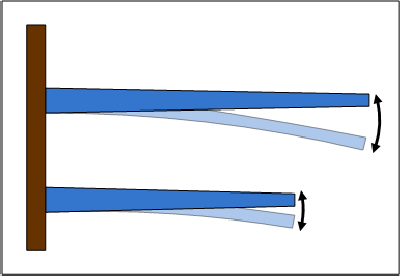

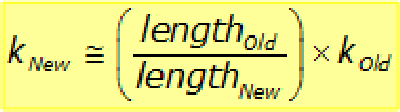

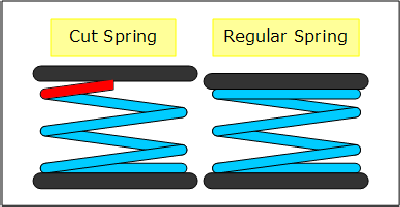

When a spring is cut, the overall length of the coil wire is shortened, which increases the spring constant. This can be visualized by comparing two diving boards, as seen below.

The short diving board is stiffer than the long one. The spring constant of a cut spring is roughly equal to the ratio of the old overall length to the new overall length multiplied by the old spring constant.

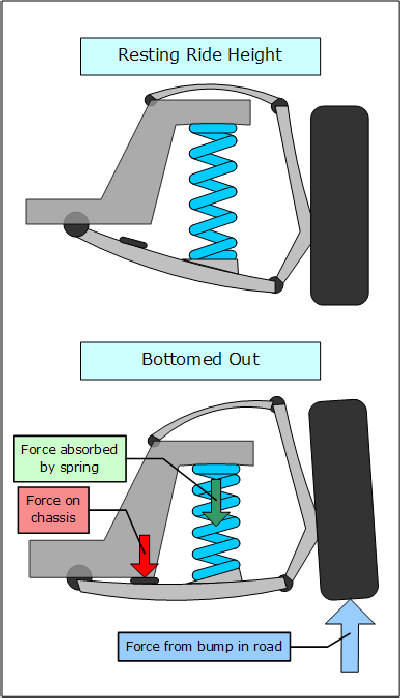

When the tire of a car goes over a bump, an upward force is sent through the suspension to the springs. The springs will absorb the energy by deflecting by a certain distance, depending on the value of the spring constant and the magnitude of the force from the bump. Bottoming OutDue to packaging and other constraints, a car's suspension can only travel so much before bottoming out. When this happens, the spring will no longer absorb any more energy from the bump, and the remaining energy will be sent to the chassis and passengers. This is an unavoidable condition, which is why cars are designed to handle a reasonable amount of force being transmitted to the chassis.

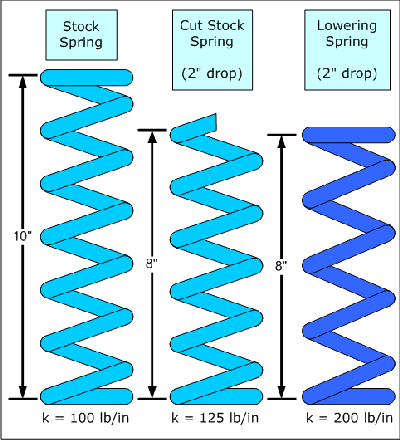

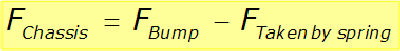

The force that the chassis will receive from the bump is equal to the force of the bump minus the force taken by the spring. Lowering a CarThe springs play a key role in the car's ride height. The weight of the car itself places a force on the springs, which deflect until all of the force from the weight has been absorbed. At this point, the spring is said to be in equilibrium, and the car will be resting at its ride height. Lowering a car is as simple as fitting springs which will have a lower total height when the weight of the car is placed upon them. There are two main approaches which can be taken to achieve a different spring height, one is to cut the springs which came with the vehicle, and the other is to replace them with lowering springs. A lowering spring will be shorter than a stock spring when unloaded, and will have a higher (stiffer) spring constant as well. A cut stock spring will also be shorter (obviously), but unlike the lowering spring it will have a spring constant which is likely not significantly greater than before cutting. If the spring was cut using a method which caused the spring to heat up significantly, the spring constant may actually be lower than before it was cut. Suspension Travel and Chassis LoadA lowered car will have less suspension travel before bottoming out. Because of this, the spring must absorb the same amount of force as the stock spring in a shorter distance. This implies that a spring with a higher spring constant must be fitted. In the example below, the stock spring has a resting loaded height of 10 inches. The car will be lowered 2 inches, using either a stock spring which has been cut or a lowering spring. With the stock spring, the suspension has 4 inches of travel before bottoming out.

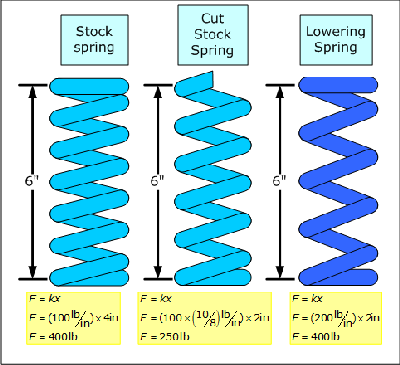

Comparison of the three springs. If the suspension at stock ride height has 4 inches of travel, and the stock spring has a constant of 100 lb/in, then the spring will absorb up to 400 lb of force before the suspension bottoms out. If the stock spring is then cut so that the resting height is the desired 2 inches lower, then there is 2 inches of suspension travel left. The spring constant is roughly equal to the old constant multiplied by the length ratio, so the spring can absorb only 250 lb of force before the suspension bottoms out. If a 2 inch lowering spring with a spring constant of 200 lb/in is fitted, the spring will be able to absorb 400 lb/in before the suspension bottoms out, as was the case with the stock spring. Below is a diagram showing the three springs when the suspension has bottomed out.

The cut stock spring takes only 250lb to bottom out, while the stock spring and lowering spring takes 400lb. If a car goes over a bump which creates a greater force than the spring can absorb before bottoming out, then the remainder of the force will be sent to the chassis. Below is the equation for determining the force which would be transmitted to the chassis if the suspension were to bottom out.

The force that the chassis will receive from the bump is equal to the force of the bump minus the force taken by the spring. In the previous example, the stock spring would absorb 400lb of force, as would the lowering spring. The cut stock spring would only absorb 250lb of force, meaning that a significantly larger force would be transmitted to the chassis when going over large bumps. A car's chassis is only designed to handle a certain amount of force, and the cut lowering spring would be sending a greater force to the chassis. Because the cut stock spring's ability to absorb energy before bottoming out is so low, the suspension would bottom out much more often than with the other springs. For example, a 300 lb bump force would not bottom out the stock spring or the lowering spring, but it would bottom out the cut spring. Ride quality would suffer as a result of bottoming out frequently. All materials suffer from fatigue (from the French word fatigué, meaning "tired"), which is failure caused by cyclic loads. In the case of a cut spring, it is placing loads on the suspension and chassis far more often than the car was designed for, which over time could cause component failure, which could be very dangerous. Effect on HandlingCut springs also negatively affect a car's handling. When the suspension bottoms out, the chassis is unsettled by the sudden large force being sent to it from the suspension. Because a cut spring will be sending a very large force to the chassis, the car will lose grip more readily. This causes a reduction in handling predictability, and hurts performance on rough surfaces. Fitment IssuesThe ends of helical coil springs are made to be flat so that they fit properly into their retainers, and so the load is distributed evenly around the retainer. Cut springs have an angled end which concentrates the load on the retainer, and in some circumstances could pop out while driving.

Cut springs do not fit into the spring retainer properly. Getting Away With ItMany people have gotten away with using cut springs on their vehicle. In some circumstances, cutting springs is not a big deal. Some of these are listed below.

Even if one or more of the above conditions are met, cutting springs may still be a bad idea. Spring manufacturers rarely honour warranties on cut springs, and the ability to judge whether using cut springs will work or not is probably outside of the capabilities of the person making the decisions. ConclusionCutting springs to lower a car is an attractive option because it is cheap. It is also easy to get the exact desired ride height by cutting small sections until the ride height is correct. However, it cannot absorb forces from bumps correctly, which lowers ride quality, spoils the handling and causes unnecessary wear on suspension components. Cutting springs will in fact lower a car, but so would flattening the tires. See Also |

|

|

|||||

|

|